News

Project for Researching Corrosion Inside Monopiles Started | 2023

Corrosion inside monopiles is a widespread phenomenon in offshore wind farms, but the knowledge about its origin and impact on the life time is very limited. JBO is investigating the phenomenon in an interdisciplinary collaboration with the Kiel University of Applied Sciences, the GEOMAR Helmholtz Center for Ocean Research Kiel and Krebs Korrosionsschutz GmbH. The project “Microbial Fe corrosion and possible corrosion protection measures in the monopile of offshore wind turbines (MiCorFe)” is funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) over 3 years.

Do you want to learn more? Get in touch with JBO’s expert Dr.-Ing. Gerrit Haake, Offshore – Head of Certification & R&D.

Further information: https://idw-online.de/de/news822927

AGILE DESIGN - JOINT SHM AND FOUNDATION DETAILED DESIGN APPROACH | 2023

JBO & WÖLFEL Wind Systems

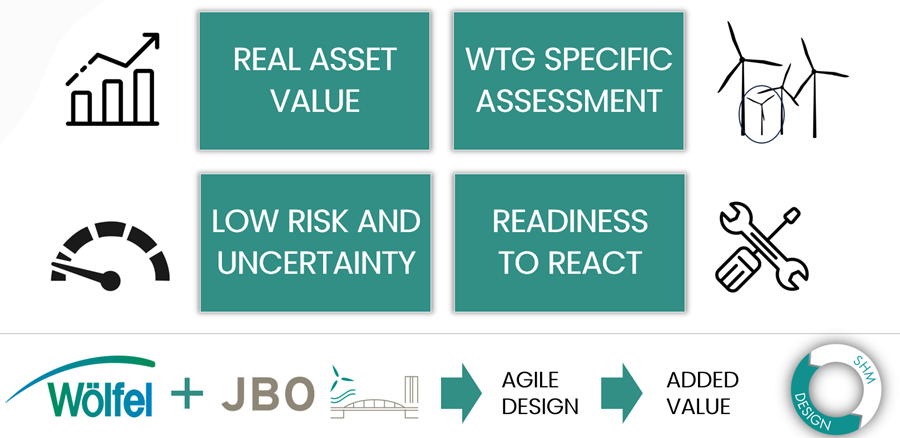

The SHM provider Wölfel and JBO have united their expertise and developed the Agile Design approach. Based on the SHM system output JBO will bring in their deep knowledge on offshore wind structural foundation design and dynamics. This allows for a detailed reassessment of the existing structures based on as-built information and measurements.

Please see also the discription of the innovative Agile Design approach on our partners website: https://www.woelfel.de/shmfoundation-agile-design.html

Agile Design Model

An Agile Design model will be setup and parametrized by JBO that reflects the real physical foundation. The model will be used to simulate and predict the performance of the physical structure on a regular basis.

Motivation

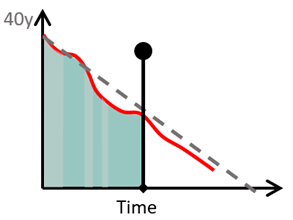

The offshore wind sector is pushing the limits since years. JBO desires to create the awareness that OWT are much more dynamically driven with size and hence highly sensitive to lifetime assumptions.

Continuous SHM combined with deep foundation design expertise is the key to reduce these uncertainties and risks. Furthermore, lifetime extension is seen as major contribution to improve the sustainability in offshore wind design.

JBO Role & Capabilities

JBO will analyse the design and as-built documentation package. Environmental conditions (wind, wave, ice, seismic, etc.) are updated and a structural model will be set up. A detailed geotechnical re-analysis based on 3D-FE methods allows to accurately reflect the soil-pile interaction. By application of the agile model a lifetime assessment based on SHM data predicts the real damage.

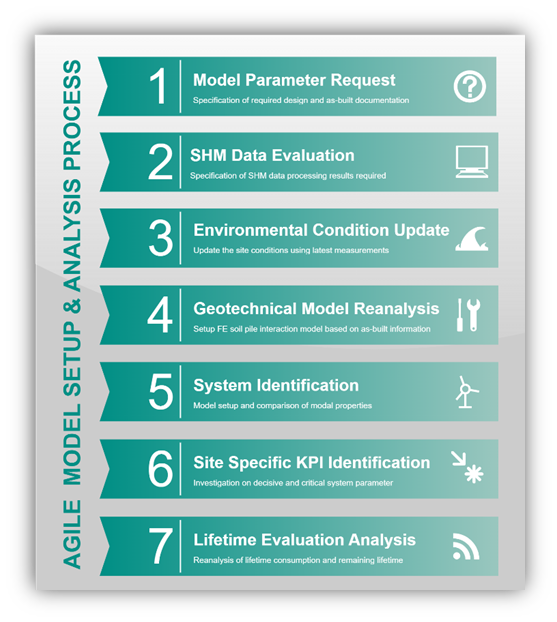

Sharp Interfaces

JBO and Wölfel developed a clear design model process that defines the workflow of the Agile Model setup.

Outcome

The added value of the Agile Design process is a real time assessment of each structure’s lifetime, and a WTG specific traffic light classification of the design relevant KPI’s of your structures. It will provide you the real asset value for each specific turbine and reduces the operators risk by having all relevant key parameter monitored.

What’s next

Feel free to contact JBO to get further information on the agile design process. We will further elaborate on the importance of joint SHM and detailed design insights and demonstrate how this will add value to your project.

Wind power without long wait | 2023

JBO is starting together with RWE and Ruhr-Universität Bochum a new research project for the accelerated expansion of wind energy on difficult soils.

For this purpose, JBO has around €74,000 in funding from the Federal Ministry for Economic Affairs and Climate Action.

JÖRSS - BLUNCK - ORDEMANN takes over OWT Offshore Wind Technologie starting May 1st, 2022 | 2022

With the takeover of OWT Offshore Wind Technologie, Jörss – Blunck – Ordemann (JBO) is further expanding its range of services as an engineering and design consultancy with the additional coastal location in Leer. In doing so, JBO also secures the experience and knowledge of the engineers at OWT.

"OWT has a long tradition and has grown over the years, especially in on- and offshore wind energy. This fits perfectly into our engineering service portfolio and is an important step in JBO's continuous growth strategy towards a sustainable energy supply. We are very pleased to welcome these experienced and competent colleagues on board," says Dr Falk Lüddecke, owner and managing director of Jörss – Blunck – Ordemann.

Jörss – Blunck – Ordemann, a design and engineering consultancy with half a century of experience and now more than 60 employed engineers, is a highly competent partner in the offshore wind energy sector. With offices in Hamburg, Berlin, Osnabrück, and now also Leer in East Frisia, JBO is very well positioned with its experienced staff for the various tasks from first design sketches to fabrication planning as well as testing and construction supervision for national and international offshore wind energy projects.

OWT is well known in the onshore and offshore wind energy industry as an engineering consultancy for steel construction. OWT has gained an excellent reputation in the market over the past years, focusing on planning, maritime construction, and offshore wind energy structures.

Merry Christmas & Happy New Year | 2021

We are approaching the turn of the year 2021/2022 with great strides. We wish all our customers, partners and friends a Merry Christmas and a good health and success for the year 2021.

The farewell year 2021 was a challenge for many companies. Regardless of the challenges in the new year, we will continue to be available for you in the usual way to support and advise you in every possible way.

Your Jörss-Blunck-Ordemann GmbH team!

#merrychristmas #happynewyear #holiday

Lots of space for our "little people" | 2021

Jörss-Blunck-Ordemann GmbH and the Acollage architecture office are pleased that the AWO Kita building project is about to be completed. Jörss-Blunck-Ordemann GmbH has taken over the service phases 1–5 of the structural engineering. Despite the large spans, it is Jörss-Blunck-Ordemann

GmbH succeeded in developing an economical supporting structure.

Due to the cost-effective construction, the AWO is able to implement further charitable projects.

#Kita #structure planning #economical #structure #building

Visualization: acollage. architektur urbanistik

Architecture: acollage. architektur urbanistik

We give full power! | 2021

JBO pool vehicle fleet now with electric car.

With the change of location from Isestraße to Kaiser-Wilhelm-Straße, we have added an environmentally friendly BMW I3 to our pool vehicle fleet.

Because we have many power connections for charging the battery due to the city location and the car is perfect, especially for short trips in and around Hamburg, the small electric speedster is very popular with our employees.

#poolvehicle #environmentallyfriendly #electrocar #hamburg

JBO company event | 2021

An unforgettable #company event is behind us. 🎉🥂

After a long Corona break, it was incredibly fun to meet everyone in person for the traditional #companyevent. Taking “3G” into account, we started with a harbor tour through Hamburg's port and landed with a lot of momentum in the Golf Lounge. Afterwards we celebrated with plenty of food and drink and a few rounds of mini golf. Simply overwhelming!

We are incredibly proud of this incredibly great team. Thank you all for this spirit! We missed these joint activities and are happy to be slowly returning to normal.

We are already looking forward to 2022 with you! #Companyevent #Teambuilding

Wind energy - digital building monitoring should make offshore plants more efficient | 2021

The project, funded by the Federal Ministry for Economic Affairs and Energy, aims to predict and plan offshore repairs more cost-effectively. It is no secret that offshore wind energy plays a decisive role in Germany’s goal for climate neutrality, and the joint project aims to make periodic tests simpler and more efficient at the same time to support Germany’s climate neutrality goal.

JBO brings its diverse BIM (Building Information Modeling) experience from its onshore projects offshore to support the digitalization of inspection and maintenance for offshore wind farms.

Lüddecke, F.; Zipfel, B.; Schwedler, M.; Al Otaibi, W. | 2021

Vibration-installed monopile foundations for offshore wind turbines https://doi.org/10.1002/stab.202100021

Offshore Wind - Energy | 2021

lightweight constructions enable the reduction of CO2. JBO is a partner of the research project "Smart Weld". The aim of this project is the reduction of costs, weights and CO2 emission for Jacket foundations

Joint industry project launched to increase understanding of monopile buckling to extend lifetime of offshore wind assets | 2021

Looking forward to work with Bundesanstalt für Materialforschung und -prüfung and Technische Universität Berlin on the joined industry project VERBATIM aimed at investigating pile-tip buckling during the installation of large diameter monopiles.

The project is funded by the Bundesministerium für Wirtschaft und Energie and many major energy companies, administered by Projektträger Jülich, Forschungszentrum Jülich GmbH , and supported by The Carbon Trust. We are grateful for the trust placed in us by granting this research project with impact on the entire #offshorewind industry.

https://www.offshorewind.biz/2021/05/24/offshore-wind-majors-tackle-monopile-buckle/

Great news from Germany! | 2021

Jörss - Blunck - Ordemann GmbH (JBO) was selected as foundation designer for the He Dreiht OWF. We are looking forward to Partnering with EnBW to develop this project.

https://www.offshorewind.biz/2021/02/19/enbw-picks-he-dreiht-foundations-designer/

New Senior Loads Expert at JBO | 2021

As of May 2021, Dr.-Ing. Wojciech Popko will join JBO, where he will serve as a Senior Loads Expert focused on the global dynamic of OWTs, floating support structures, and sea ice loads topics. He will also strengthen our team with a profound understanding of verification and validation of aero-hydro-servo-elastic codes. Dr. Popko has more than ten years of experience in project management, technical execution, and the lead of international R&D and industrial projects with partners and clients across the EU, the USA, and Asia. He is also a recognized author of multiple peer-reviewed articles and conference publications in top international journals and conference proceedings. Before joining JBO, Dr. Popko worked as a researcher and a project manager at Fraunhofer IWES. In 2020 he obtained his doctorate from the Leibniz University Hannover.

https://www.linkedin.com/posts/j-b-o_engineering-offshorewind-jbo-activity-6796049567134617600-lS5o

New Senior geotechnical expert at JBO | 2021

From April 2021 onwards, JBO enlarges the scope of geotechnical design services. This covers the elaboration of geotechnical interpretative reports and the geotechnical foundation design for wind turbine generators and substations.

Kirill Alexander Schmoor, among other colleagues, will be responsible for this topic.

Kirill is experienced in the design of offshore foundation piles and suction buckets, including the analysis and interpretation of geotechnical soil profiles and laboratory tests and the application and evaluation of special design methods. He worked on more than 20 offshore projects dealing with offshore foundation piles' design and elaborating geotechnical interpretative reports and several research projects.

New lead geotechnical expert at JBO | 2021

From April 2021 onwards, JBO enlarges the scope of geotechnical design services. This covers the elaboration of geotechnical interpretative reports and the geotechnical foundation design for wind turbine generators and substations.

Klaus Thieken, among other colleagues, will be responsible for this topic.

Klaus is experienced in the design of offshore foundation piles and suction buckets, including the analysis and interpretation of geotechnical soil profiles and laboratory tests and the application and evaluation of special design methods. He worked on more than 40 offshore projects dealing with offshore foundation piles' design and elaborating geotechnical interpretative reports and several research projects.

Wegener, F., Seidel, M., Glienke, R., Marten, F., Schwarz, M. | 2020

Numerical simulation of loss of prestressing force in ring flange connections. steel construction, https://doi.org/10.1002/stab.202000055

Seidel, M., Wegener, F., van Dijk, I. | 2020

Influence of flange dimensions and geometrical imperfections on stress concentrations at welded flange necks. Steel construction, 89: 932-943, https://doi.org/10.1002/stab.202000021

Haake, G., Bolm, I., Zurborn, H., Szałyga, M., Jayakodiy, S., Ostermann, F., Al Otaibi, W. | 2020

Design development of a floating platform for a self-aligning offshore wind turbine, DESPOW final report, technical information library, https://www.tib.eu/de/suchen/id/TIBKAT:1726724387/DESPOW-Design-Entwicklung-einer-schwimmenden-Plattform?cHash=9e2acd6ee2e3a820611e24f595a38073

Wegener, F., Schwarz, M., Glienke, R., Marten, F., Seidel, M. | 2020

Numerical modeling of the force-deformation behavior of prestressed bolts in L-flange connections. Steel construction, 89: 266-281. https://doi.org/10.1002/stab.201900113

Glienke, R., Wegener, F., Gericke, A., Hobbacher, A.F., Henkel, K.‐M., Marten, F., Günther, H.‐P. | 2019

Experimental and numerical investigations on fatigue strength on welded details in tubular steel towers for wind turbines. Steel construction, 88: 968-987. https://doi.org/10.1002/stab.201900069

Lüddecke, F., Victor, A., Schwedler, M. | 2019

Analysis of the influence of manufacturing-related imperfections on the bolt force on large ring flange connections. The test engineer, issue 55: 42-57, Federal Association of Test Engineers for Structural Engineering, November 2019 https://www.bvpi.de/bvpi/de/aktuelles/abonnement-der-pruefingenieur.php

Brendike, A., Ostermann, F., Lüddecke, F. | 2018

“Offshore wind jacket foundation design challenges in earthquake regions”, steel construction 2018, DOI: 10.1002/stab.201810049

Schwedler, M., Dörfeldt, S., Lüddecke, F., Seidel, M., Thiele, M. | 2018

Factors influencing the pretensioning force of screws with diameters up to M72 in ring flange connections. Steel construction 87 (2018), Heft 2

rank.Ostermann@j-b-o.de

rank.Ostermann@j-b-o.de