Research and Development

ONE STEP AHEAD TO THE STATE-OF-THE-ART

Apart from planning, testing and consulting tasks Jörss - Blunck - Ordemann GmbH is increasingly committed with questions

that fall into the field of research and development. On the one hand, these are development tasks for

in-house tool development and process optimization, which are financed purely from own funds.

In addition, a significant part of the R&D activities at JBO is supported by public funding

(Federal Government and European Commission) or by the industry. The activities performed go

from basic research to application-oriented development.

The following research projects are shown as examples:

DESPOW in the joint project HyStOH

DESPOW = Design Development of a floating platform for a self-aligning offshore wind turbine

HYSTOH = hydrodynamic and structural mechanical optimization of a semi-submersible offshore wind turbines

Project partner

- Cruse Offshore GmbH

- Technische Universität Hamburg

- aerodyn engineering GmbH

- Germanischer Lloyd Industrial Services GmbH

Running time

2016-2019

Funded by

Federal Ministry for

Economy and Energy (PtJ)

Funding volume JBO

about 250.000 €

Project description

The project deals with the investigation and optimization of a self-aligning semi-submersible platform for floating offshore wind turbines (OWT). The basic idea of the concept is to use the aerodynamic forces of the turbine and tower structure for the independent alignment of the turbine in the wind in order to achieve a high energy yield with a simple system design. The floating platform means that it can be installed in coastal areas, and only tugs are required for installation. The overall system structure - starting with various conceptual drafts - is iteratively optimized in the interdisciplinary project using various methods. System technology, aerodynamics, structural design, production and logistics are closely interlinked. Within the consortium JBO is responsible for the structural design and deals with the topics of design basis, load determination, anchor system, corrosion protection, floating stability, collision friendliness and manufacturing and assembly concept, from the preliminary draft to the basic design. A special feature in the design of the supporting structure was the requirement that it should be built in panel construction as much as possible, based on shipbuilding principles. The fatigue calculation proves to be a particular challenge, as the impact situation for this construction method was largely unknown. The planning methods used within the scope of the project are evaluated with regard to their reliability and contribute significantly to the planning and certification security of future projects.

More informations

www.cruse-offshore.de

Representation of the floater in the design stage

Source: Cruse Offshore GmbH

Welded steel knots for offshore jackets

Design optimization using innovative calculation approaches and derived manufacturing processes for reducing

the use of materials and the production costs

Project partner

Salzgitter Mannesmann Renewables GmbH

Running time

2017-2021

Funded by

Federal Ministry for Economic Affairs and Energy (AIF)

Funding volume JBO

about 170.000 €

Project description

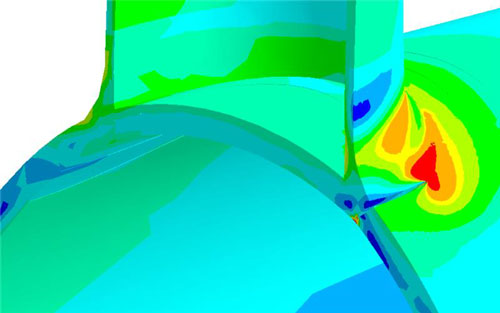

Due to its ever increasing dimensions, the monopile as a foundation type is reaching the limits of its usability in deeper waters. Jacket structures offer a promising alternative for this, but one that still has weaknesses in the area of welded nodes. The research project reduces the need for development in terms of design and production with regard to the welding process, weld seam geometry and the verification of fatigue, in order to prove the jacket to be a competitive and therefore future-oriented alternative. There is optimization potential in the structural dimensioning (mass) through interaction with the manufacturing conditions (welding). The detail "welded joint connection" is decisive in the state of fatigue and therefore determines the dimensions of the overall structure. A more precise determination of the fatigue resistance can result in a reduction of up to 30% in the degree of utilization for the welded joint connections. The optimized design and the resulting thinner tubes save costs and time during manufacture. However, the existing engineering methods in existing standards and guidelines do not offer any possibility for further optimization taking into account the positive effects of improved geometry, further developed manufacturing methods and material qualities. In the project, innovative fracture mechanical methods are used in the dimensioning and optimization of the weld seam geometry as well as automated welding processes to improve the production quality. The aim of the project is therefore to develop new design methods in order to be able to provide an economical construction as a competitive solution.

Numerical simulation of crack propagation in a welded pipe connection

ReaLCoE

Next Generation 12+MW Rated, Robust, Reliable and Large Offshore-Wind Energy Converters for Clean,

Low Cost and Competitive Electricity

Project partner

- Senvion (bis Oktober 2019)

- BIBA

- DTU

- Uptime Engineering

- 8.2

- Principal Power

- Ingeteam

- ECN

- DNV GL

- EnBW

- ABB

- wood.

- Fraunhofer IWES

Running time

2018-2021

Funded by

European Commission

Funding volume JBO

about 310.000 €

Project description

ReaLCoE deals with the development up to the prototype testing of a new offshore wind turbine of the 14-16MW generation regarding the reliability, the modular structure and the reduction of the LCOE. JBO is represented in the consortium as a specialist for innovative support structure concepts in terms of a holistic design. The creation of a representative design basis, the development and comparison of several bottom-fixed foundation variants are on the work plan as well as the optimization and BSH-based dimensioning of the supporting structure for the final system configuration. In the sense of a holistic view, innovation potential with regard to damping behavior, production of the components and the interface definition of the components is exploited. With the resulting optimized design of the supporting structure, the overall project is supplemented by an essential module and the costs of future offshore wind projects are reduced.

More informations

www.realcoe.eu

VERBATIM

"Verification of the Buckling Assessment and Behaviour in Large Monopiles"

"Verification of the Buckling Assessment and Behaviour in Large Monopiles"Sub-project "Simulation based Buckling Assessment and Behaviour in Large Monopiles"

Project partner

- Bundesanstalt für Materialforschung und -prüfung

- TU Berlin mit Unterstützung durch den Offshore-Wind Accelerator unter Koordination des Carbon Trust

Running time

2020-2022

Funded by

Bundesministerium für Wirtschaft und Energie (PtJ)

Funding volume JBO

about 150.000 €

Project description

The aim of the joint project is the better predictability of two phenomena in monopiles. On the one hand, the pile tip buckling is considered, which appears when imperfections occur when driving monopiles, e.g. triggered by uneven loading or boulders. Conventional and highly conservative dimensioning methods often represent the dimensioning load case for large diameters. On the other hand, the problem of buckling in the area of the seabed, which can occur due to the sudden load change during operation, is considered. In this context, JBO deals with numerical simulation and innovative methods of verification and their validation based on test data. The project is supported and accompanied by numerous industrial partners who are united in the Offshore Wind Accelerator and guarantee a high level of practical relevance.

In addition, JBO participates in numerous research projects in the project-accompanying committee.

This guarantees, on the one hand, a constant exchange on current research and development topics for JBO, and on the other hand, via the cooperation JBO has an extensive network with research and industry partners as well as standardization groups and authorities.

Information on further completed or ongoing research projects can be provided on request.

contact person

Dr. Gerrit Haake